J. Craig Venter Institute

Project Overview

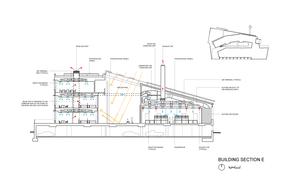

The client’s commitment to environmental stewardship initiated the challenge for the design team to create a net-zero energy (NZE) laboratory for its new West Coast research institute, which resulted in a 44,607 SF building comprised of a single-story laboratory wing and a three-story office / administrative wing framing a central courtyard, all sitting above a below-grade parking structure for 112 cars. The new facility was designed to achieve LEED-Platinum certification and a net-zero energy footprint, making it the first such biological laboratory in the country. The courtyard serves as the heart of the Institute, drawing researchers across and into the collaborative outdoor space. The project uses a modest palette of materials: high-performance glazing, Spanish cedar wood, and high-strength concrete. Each material was considered for its contribution to the enhancement of the building’s performance, resulting in a building that is both functional and artful in its simplicity.

Design & Innovation

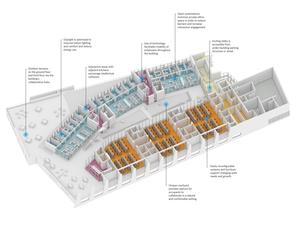

The project was shaped by a remarkable site—2.03-acres in the Upper Mesa Neighborhood of La Jolla, on land leased from the University of California, San Diego (UCSD), with views to the Pacific Ocean. Because the site is situated on the edge of La Jolla’s Skeleton Canyon Ecological Reserve, a precious natural resource that is used for research and education for promoting the understanding and protection of biological resources, it was critical to respect the Reserve both during and after construction. Also imperative was accommodating the program, which called for both laboratories and offices—two distinct types of spaces in terms of ventilation and energy use. The team’s holistic approach to design revolved around energy performance and water conservation. To reduce energy loads and optimize the mechanical system, the computational laboratories and administrative spaces are located in one wing, and wet laboratories occupy the other. Ground level wet laboratories utilize an easily reconfigurable “plug and play” casework system that encourages transparency and creates an environment that can be rearranged overnight. The dry wing provides open and private offices, formal meeting areas, temporary visitor stations, and informal open modular seating to support administrative and research activities and to foster collaboration.

Regional/Community Design

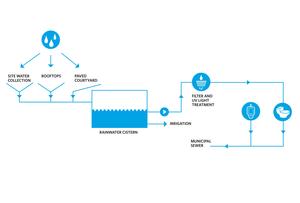

Site improvements were based on design principles developed in the Scripps Institution of Oceanography Upper Mesa Neighborhood Planning Study. Recognizing that the site’s primary advantage was its view of the ocean and adjacent Ecological Reserve, the building’s orientation and landscape design were planned to highlight these features and create positive connections to the immediate neighborhood, while responding to local climate and site influences. The building’s configuration on the site also provides the groundwork for linking the building’s terrace and first level to a future promenade and to future UCSD research buildings. Also considered was public access around and through the site via all-weather paths. And, since water conservation is a prime driver in the San Diego region, in addition to a 60% reduction in domestic water consumption, the facility also utilizes captured stormwater for reuse in the toilets and cooling tower, as well as drought resistant landscaping. Finally, the facility is pre-piped to allow the use of regional reuse water, once put into operation by the City.

Metrics

Land Use & Site Ecology

Capitalizing on the site’s extraordinary connections to the Pacific Ocean and Skeleton Canyon Ecological Reserve, the design extends the landscape’s character along the western edge of the property, merging the land with the building’s terraces—creating continuity with the canyon and natural surroundings. The architecture was influenced by the density of the site, the climate, programmatic requirements, and their supporting infrastructure. It was also important to be a good neighbor, with a domestic scale that fits with the residential neighborhood to the east. A popular soccer field was not only left untouched by the construction of this building, but it offers yet another pleasant vista looking south from inside the laboratories, or outside on the terrace. As previously mentioned, the Reserve was not affected. Finally, La Jolla is a perfect place for a high-ventilation laboratory building, due to the mild climate, since heating and cooling of enormous amounts of ventilated air could be minimized.

Bioclimatic Design

The deliberate inclusion of large windows in both wings, even in the laboratories, also meant compensating for glare at certain times of the day. The set of deep eaves on the southern exposure minimizes the hours of direct sunlight into the laboratories, while still admitting ample daylight onto the benches even on cloudy days. Two arrays comprising 26,124 SF of photovoltaic surface serve as both an energy source and a shade structure, leveraging the resource and mitigating the challenge of sunny Southern California days. The PV array was configured to provide shading of the western patio area, while the PV panel over the interior courtyard provides a diffused light into the space and allows reflective light off the concrete walls to ‘bounce’ light into the northern benches of the laboratories. It is predicted that the arrays will exceed the building demand, pushing excess power generated back into the grid. Spanish cedar, often use to build boats, was used in the exterior wood wall system. Not only will this wood stand up to the seaside climate, but it will age naturally, without the use of harsh chemicals.

Light & Air

Regardless of one’s location in the building, each occupant can maintain a connection to nature via unobstructed views outdoors through large windows. Even the garage has openings that allow for its natural ventilation, while providing views out to the landscaped grounds and natural surroundings. Office occupants have views north or to the courtyard. Laboratory occupants have views south and also into the courtyard. The windows that look into the courtyard, also provide connections among occupants. The use of overhangs and shading devices, in combination with automatic and manual shades that mitigate glare issues, provide day-lit spaces, even on a cloudy day, such that 80-90% of the occupants rely solely on daylight during daylight hours. Occupant control features include over-ride of the automatic shades, light-level control down to an office level, and operable windows in all office areas. Conditioning only the ventilation air required for the space, allowed for the use of a 100% OSA system for the offices. Internal and external loads are mitigated via hydronic heating and cooling, primarily via induction beams—chilled beams that have cooling and heating capabilities.

Metrics

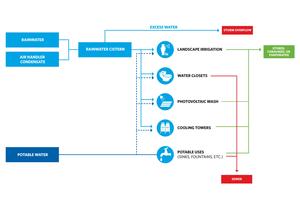

Water Cycle

A complex water-balancing model was developed to understand the quantities, frequency, and demand times of water use. The result is a system that uses rain and recycled water, when available, for everything except potable water uses. Plans for a greywater connection to the building (known in California as “purple pipe”) have also been established to allow for use of reclaimed water in the future. Because La Jolla has a distinct rain season that runs from November through February, and then is relatively dry the rest of the year, the team maximized the capture of rainfall for reuse in the building, using a combination of two civil cisterns and one storage tank under the garage, which provide 95,000 gallons of rainwater storage. Combined with AHU condensate reclamation, this equates to capture of two 100-year, back-to-back rains. Additionally, this storage extends utilization of reuse water almost through the summer months, at which time domestic water can be used for back-up until reclaimed water from the utility is operational.

Metrics

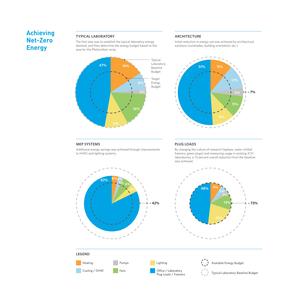

Energy Flows & Energy Future

The project’s NZE approach led to several integrate strategies. First, unlike buildings that use electricity for cooling, then reject building heat into the atmosphere, and burn gas at night for heat generation, this project utilizes a 50,000-gallon Thermal Energy Storage (TES) system as the primary conditioning driver. Cooling towers cool the TES at night; allowing the building to be conditioned most days without electrical chillers. As cooling is drawn out of the TES, it’s replaced with warm water that can be used at night for heating purposes. Additionally, reject heating is captured from a separate water loop feeding a water-cooled, low temperature (-80F) freezer farm, and an exhaust air heat recovery from the laboratory exhaust air. This is one of the few buildings, and the only laboratory in California, that does NOT have a natural gas line extended to it, meaning no on-site burning of fossil fuels is taking place to generate heat or for other uses, except for the diesel fire generator, used for life safety and minimal stand-by power for laboratory equipment. Furthermore, a large photovoltaic array is sized to over-produce most of the year, pushing energy into the grid and putting the NZE goal within reach.

Metrics

Materials & Construction

The project uses a modest pallet of materials: high-performance glazing, FSC certified Spanish cedar wood, and concrete. The use of glass was a balance between heat gain and daylight harvesting capability, to maximize the overall energy model. The wood is from renewable forests, and it was decided early in the design process to leave the wood untreated, to alleviate the need for harmful chemical finishes. The untreated wood also require less maintenance over time, making it a more sustainable product. The cement used in the concrete is Portland Type III, because of its naturally lighter color. This was consistent with the UCSD neighborhood plan guidelines, but also was an energy consideration because of its inherently greater heat reflective characteristics. It was also engineered as 8000psi high-strength concrete, to minimize the amount of concrete required and to also use 30% fly ash to increase the percentage of recycled content, thereby making the concrete one of the most sustainable design mixes ever used in the US at the time of construction.

Long Life, Loose Fit

The Institute’s decision to locate the 50+ year facility in La Jolla, on property leased from the University of California, posed some unique challenges. Given the extremely aggressive goals for achieving sustainability for the project—beyond LEED Platinum—meetings were held with the utility agencies, the University, and the Fire Marshal to facilitate discussions of how the unique elements of the design could be approved, even though they were not consistent with the current campus design standards, the municipal regulations, and, in some cases, building codes. As an example, while the project would connect to the local sewer system, the original design included a constructed wet-land to treat on-site sewer waste and use the reclaimed water for irrigation and cooling. The City was also introduced to an element of the Institute’s research, which using intercept connections could further extract waste from sewage streams to generate electricity and whose only other bi-product is fresh water. Discussion of how the fresh water could be used in the building is ongoing.

Collective Wisdom & Feedback Loops

Laboratories, particularly genomic-focused ones, traditionally consume large quantities of energy to run energy-intensive scientific equipment and for heating/cooling. The client was determined to make his facility the exception. It was decided early on that the building was to be a true net-zero for energy, generating 100% of its power on site. On-site renewable energy is generated through the sizeable photovoltaic roof. Due to the fast-track nature of the project, construction of the architectural concrete structure was well underway while MEP coordination and design of the enclosure and finishes was also in process. This required exceptional coordination to ensure block-outs and embeds were located correctly. The contractor was brought in early to perform preconstruction with the goal of significantly lowering the initial estimated construction costs while still allowing the client to achieve LEED Platinum status. Now in operation, the building uses a fully integrated open protocol controls platform to make building data available to operators, consultants, and researchers. JCVI La Jolla was always intended to be a teaching tool. Members of the project team regularly speak at conferences around the country addressing the challenges of ZNE design and construction.

Other Information

Due to a difficult financial period following completion of Design Development, the client considered moving into market-rate laboratory space in lieu of constructing the new building. Following a series of collaborative team meetings, however, regarding alternative solutions, the architects were tasked with modifying the building design to compete with developer models, while at the same time not jeopardizing the net-zero performance. As a result, some of the more complex water treatment systems, with hard to justify lifecycle costs, were eliminated. However, we were able to retain the space and infrastructure in the building to allow for future growth to accommodate elements such as a bio-reactor, which is part of this client’s research. Even though the client was not willing to relinquish the energy performance of the project, with these previously mentioned solutions, the budget was reduced by approximately 70% of the original estimated project cost. The functionality remains the same; a highly flexible laboratory building that is on track for LEED-Platinum certification, with a net zero annual energy usage (total energy usage annually at $0), zero carbon usage (no offsets, off-site generation, or use of petroleum or natural gas), and 100% collection and reuse of on-site rainwater.

The client's vision was to build the most sustainable research building in the world, setting a new benchmark in environmental stewardship. The hope was the lessons learned from designing and constructing this building could be used as a role model by other institutions around the world to improve how laboratories are built and operated. Key to meeting the goal to be net-zero energy and net-zero wastewater was an approach where the architect worked with the researchers to reduce the demand loads, look for passive approaches, augment them with active systems where the loads demanded it, and add renewable energy in the form of a rooftop solar array to supply the remaining energy demands. The same approach was taken on water use, with a constructed wetland system to purify gray and black wastewater. A series of “intellectual collisions” between researchers and the design team inspired the building occupants to consider ways to also green their research, and the team to design parts of the building as part of the Institute’s research. This included a bioreactor that, when scaled up from the bench top, will connect to the waste system to purify water and generate electricity for the building. During construction, mock-ups allowed the contractor to set extraordinary standards of construction quality and excellence throughout the facility. For instance, early on, the project team built mock-ups of the exterior skins, which were tested for construction integrity and to ensure they could withstand potential water and air intrusion issues. Several mock-ups were required to refine the mix design and to perfect the finishing and forming techniques necessary to provide the owner and architect with the look they desired.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Owner | Robert | Friedman | J. Craig Venter Institute | La Jolla, CA |

| General Contractor | Craig | Swenson | McCarthy Building Companies, Inc. | San Diego, CA |

| MEP Engineer | John | McDonald | Integral Group | Oakland, CA |

| MEP Engineer | Peter | Rumsey | Peter Rumsey PE | Oakland, CA |

| Lighting Designer | David | Nelson | David Nelson & Associates | Littleton, CO |

| Structural Engineer | Jefferson | Asher | KPFF Consulting Engineers, Inc. | Calabasas, CA |

| Civil Engineer | Jeff | Gavazza | KPFF Consulting Engineers, Inc. | Los Angeles, CA |

| Landscape Architects | Yaki | Miodovnik | Andropogon | Philadelphia, PA |

| Landscape Architects | David | Reed | David Reed Landscape Architects | San Diego, CA |

| Laboratory Planner | Richard D. | Kalish | Jacobs Consultancy, Inc. | Solana Beach, CA |

The jury was impressed with how this project achieved net zero for a lab. The building was well crafted from materials well suited for the marine location. Interior spaces and the courtyard were well daylit. The program connected the labs and offices across an exterior courtyard.