The Edith Green – Wendell Wyatt Federal Building

Project Overview

The Edith Green-Wendell Wyatt (EGWW) Federal Building is an 18-story, 512,474 sf office tower in downtown Portland, Oregon. Originally built in 1974, the building received funding from the American Recovery and Reinvestment Act to undergo a major renovation to replace outdated equipment and systems. This funding stipulated the project must meet the stringent energy and water conservation requirements of the Energy Independence and Security Act (EISA).

Since the building’s completed renovation in 2013, post-occupancy studies have helped to demonstrate compliance with EISA’s efficiency objectives, refine and further improve the building’s actual performance, and provide feedback to the General Services Administration (GSA) and design team for future work. These studies, which will last through January of 2016, are being conducted collaboratively by members of the design and construction teams, the GSA Region 10, GSA’s Office of Federal High Performance Green Buildings, and third-party research entities.

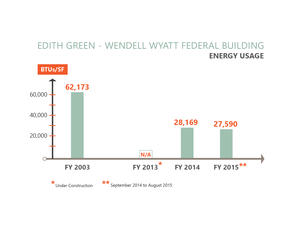

Already, EGWW has exceeded its projected energy and water saving goals. Gas and electrical utility bills demonstrate a 45% energy savings in the first two years of use, compared to a building built to code. A water model predicted the building would harvest approximately 540,000 gallons of water annually – a 60% reduction in water use compared to a typical building. But in the first two years of use, the actual rainwater collected annually was 626,544 gallons, or a 65% reduction in water use.

In a recent tenant satisfaction survey, EGWW has an overall satisfaction rating of over 75%. Although it’s difficult to correlate specific green building measures to overall tenant satisfaction, several survey comments connect these innovations to an improved experience:

“I very much appreciate […] the LEED Certification and all of the building features that meet it. Great natural lighting. Water cooling system is adequate and I appreciate the higher headroom it allows. Using recycled water in the bathrooms is a plus,” said an employee at the Bureau of Land Management.

A Forest Service staffer working in EGWW said, “I think the EGWW building is not only beautiful, but a pleasant place to work. The lighting is great, and all aspects of GSA-controlled items function appropriately.”

“The lighting provided in the workspace is such a plus!” said another Forest Service employee.

Building Manager Howard Schaffer remarked on the feedback he has received, “I hear common praise of the plants, and now being able to sit in first floor lobby, the outside eating area, or Conference Room 1, and looking through the glass at the plants.”

Since building energy use is typically unstable during the first few months of operation, a one-year stabilization period was allowed before calibrating the energy model. Data is collected and validated by the building operator through a Building Management System (BMS), utility bills, and manual meter readings.

After the one-year stabilization, the original energy models used during the construction process were calibrated, adjusting the original eQuest baseline and proposed building models to account for as-built deviations. This created a revised baseline and an as-built model to use as comparisons.

Design & Innovation

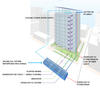

GSA’s goal for transforming EGWW from an aging energy hog to a premier green retrofit was fully embraced during design and construction. Implementation of one of the project’s biggest innovation – the replacement of the pre-cast concrete cladding with a high-performance skin – not only made the building more energy efficient, but also allowed for a radiant heating and cooling system that freed up approximately 31,000 extra square feet of net rentable space.

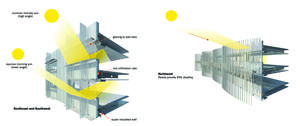

The new skin also aimed to be visually responsive to the realities of place and building type. To that end, every face of the building presents a different set of aluminum reflecting and shading elements that were modeled to respond year-round variations of the sun. Horizontal panels reflect light and provide shade on the southwest and southeast, while west-facing vertical ‘reeds’ provide relief from the low-angle sun – all without obstructing views.

As significant as the 55% energy use reduction and 65% water use reduction are, the most remarkable result of the renovation was the increased occupant satisfaction achieved. One year after moving into EGWW, tenants indicated increased satisfaction compared to their temporary quarters in a survey for the Center for the Built Environment.

Regional/Community Design

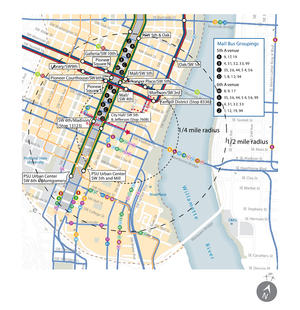

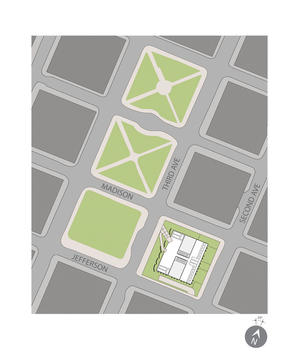

The decision to reuse the existing building was one of the greenest for EGWW. In addition to setting a precedent for how a mid-century high rise can be adapted for modern use and meet strict sustainability standards, this decision also reinforced the regional connectivity of government buildings in a key part of downtown Portland. The existing site is within the city’s central business district, and adjacent to the city hall and the federal courthouse. It’s also less than two blocks from the downtown bus mall and within walking distance of four light rail lines. The vast transit options account for a possible 283 rides per day by employees, and as a result of the renovation, 1,200 federal workers are not reliant on automobiles for transportation. The building rates impressively for active transport with a Walkscore rating of 98, a Transit Score of 94, and a Bike Score of 94.

From a design aspect, materials such exterior glass, aluminum and steel achieve improved seismic performance while also conveying the prominence and permanence desired of a government building. For the first time in 40 years, EGWW is a unique contribution to the city’s skyline.

Metrics

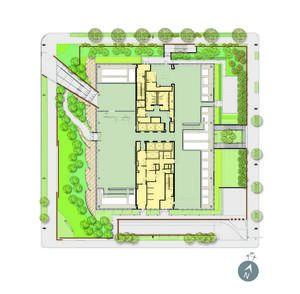

Land Use & Site Ecology

The most prominent feature of EGWW are the staggered vertical “reeds” on the west façade, which not only shade the building, but support a native ecosystem. A tapestry of climbing vines ascend the reeds, connecting the building to the ground plane and surrounding landscape – a lush arrangement of plants selected from the bio-region for their qualities of beauty, drought tolerance, soil adaptability, and compatibility with security guidelines. The deciduous vines also allow extra light into the building during winter; in autumn they provide a pop of color.

A light-weight soil matrix supports vigorous growth and allows drainage to the structure below. The soil is 20 inches deep and consists of a blend of organics, pumice and local sandy topsoil. Plants were selected, sourced, container grown, and developed for an additional season in order to target a 12- to 15-foot height at planting. Vines are spaced three feet apart on both sides of the screen, and the species are varied with each exposure to include specific functions. For instance, fragrant varietals flank the entrance and exit.

Visible from a distance, the planting scheme helps communicate GSA’s green commitment while providing a unique setting for the re-birth of this urban building.

Bioclimatic Design

Two big changes to the area surrounding EGWW occurred during construction that altered its microclimate and required adaptive responses by the building team: the removal of a building to the south, and the addition of a building to the east. With the removal of a building to the south, the zone immediately adjacent to the window would now be warmer. A thermal comfort study provided a solution: add an active radiant panel to the perimeter soffit. This not only addressed the added thermal load at the perimeter, but also provided a higher degree of thermal comfort and more uniform temperatures throughout the depth of the space.

During the thermal comfort survey, the team found reflected light and heat from an adjacent building that was not present during the design process. The survey indicated that the lowest thermal comfort response was from the lower, east-facing floors across from the new building, while the most positive thermal response was from the same floors to the south. Flexibility built into the original design allowed for a post-occupancy rezoning, which allowed for increased cooling in this area.

These situations both offer an important lesson: design for future possibilities as well as current conditions.

Light & Air

One design strategy that has proven to benefit building occupants is the use of light shelves and reflectors to enhance the building’s daylighting design. High occupant satisfaction on the upper floors on the building’s west side illustrates the success of the vertical reeds. According to the occupant survey, 65% of EGWW occupants report satisfaction with the amount office daylight. Additionally, a third-party study showed that in addition to energy savings, the effects of the daylighting helped with circadian entrainment.

Another major design strategy, use of hydronic radiant ceiling panels with DOAS, was estimated to save 10% to 15% of total building energy use when compared to a variable air volume mechanical system. Although the system provides a high level of thermal comfort and indoor air quality, it was predicted that occupants accustomed to noisily blown cool or warm air (as in traditional systems) would perceive a problem linking minimal air movement to a lack of cooling. One way this was corrected during the post-occupancy work was to adjust the range of temperature allowed to improve the balance between energy savings and occupant comfort.

Metrics

Water Cycle

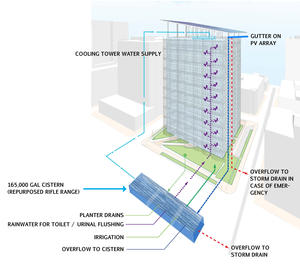

EGWW achieved greater than 65% water savings through a dual strategy of incorporating water-conserving plumbing fixtures together with a 160,000-gallon tank for collecting rainwater. Created by repurposing an underground rifle range, the tank allows rainwater to be stored and used for toilet flushing, irrigation and mechanical cooling tower makeup water. It also helps the project meet another of EISA’s goals – managing stormwater to mitigate negative stream flow effects. When rain hits the angled 180 kW solar array atop the building, it’s channeled directly to the storage tank.

Although the building doesn’t separately measure potable water for landscaping, the maintenance staff does report daily water readings. In the winter, EGWW uses approximately 10,000 gallons of water per day. During the summer months, irrigation and cooling towers consume between 12,000 to 17,000 gallons per day. Of that, between 800 to 1,000 gallons of potable water is used each day until the tank runs dry, typically in July. Over the course of a year, an impressive 626,544 gallons of rainwater has been collected and reused, the equivalent of seven competition-size high school swimming pools. During winter months, rainwater accounts for up to 85% of the total building water use.

Metrics

Energy Flows & Energy Future

Based on collected utility data, the renovated EGWW uses 55% less energy than the original building. This efficiency derives in part from an exceptional façade design featuring shading devices stretching up the entire 18-story height of the west face, and an integrated shade/light reflector system on the south and east faces. These shading strategies were key to being able to incorporate the project’s primary Energy Conservation Measure – a radiant heating and cooling system. Occupant comfort and indoor air quality are also enhanced by use of a radiant system, underscoring the fact that the building’s tenants and their productivity are the ultimate beneficiaries of this next-generation building. Employees are encouraged to contribute to energy reductions through the use of building signage touting the numerous green strategies incorporated throughout EGWW.

One significant change to the project that occurred after design was the incorporation of a server farm in the basement of the building, which allowed for the collection of waste heat for warming other areas of the building. This strategy results in additional energy savings compared to the sprinkling of servers on multiple floors.

The building is predicted to achieve an Energy Star score of 97.

Metrics

Materials & Construction

One of the systems selected both for its benefits to human health and for its energy efficiency was the radiant heating and cooling system. While better for indoor air quality than conventional systems, and incredibly efficient, one of the perceived negatives of the radiant panels was a lack of air movement, which many people equate with cooling. An important lesson learned was the importance of educating tenants on what to expect in their new environment. To facilitate this, the property management team incorporated the GSA’s green leasing and operations policy into a program highlighting the building’s green features and the impacts they have.

One focus of this program was tenant-led waste diversion. For fiscal year 2015, EGWW had an impressive 51.33% waste diversion rate, which exceeds the GSA’s goal of 50% diversion. In addition to standard recycling of paper, plastic, glass, etc., the building also participates in the offsite composting of landscape organics.

Long Life, Loose Fit

EGWW employed two major design solutions to maximize the building’s flexibility and adaptability into the future. The first was the decision to replace the building’s precast concrete cladding with a relatively light glass and aluminum system. This modification lightened the structure and allowed the building to meet today’s more stringent earthquake code without requiring a major structural upgrade – typically one of the most costly expenses in a renovation of this scale. The curtain wall also features special ‘blast-resistant glass,’ which GSA mandates for 21st century buildings.

The second innovation was designing the radiant panel ceiling system as a kit of parts, reusable in future tenant improvements. The system included 8-inch sections in addition to the standard 2-foot by 4-foot sections located in alignment with the building’s exterior mullions. The system accommodates the insertion of walls on a 5-foot grid, and is critical for long-term flexibility and adaptability. The radiant panels were also designed with disconnects that allow for the building mechanical zones to be reconfigured.

Collective Wisdom & Feedback Loops

Based on the design, analysis, and construction process alone, EGWW appears to be a remarkably successful renovation. But success lies in how well the building actually performs. Recognition of this fact has led to a set of aftercare studies and services to fine-tune the building’s performance – both for energy efficiency and occupant satisfaction.

In late 2014, occupants rated their satisfaction with the interior conditions of the building in an online survey. Lending a better understanding of the survey’s results, the same survey – from the Center for the Built Environment – was given to occupants prior to moving into EGWW, at their previous offices in downtown Portland. Overall, 69% of occupants are satisfied or very satisfied with the building; an additional 14% are neutral in their ratings.

The aftercare phase also found nuances in performance that were challenging to identify in the design phase: the thermal and light level preferences of occupants; set up and actual use of work stations; and seasonal sunlight reflections off adjacent buildings that causes glare where shades are not incorporated. For this, calibration of mechanical and lighting control systems and training of the building operators was essential, and required bridging the divide between engineering and building operations.

Other Information

The building’s post-occupancy studies allowed for an analysis of the payback on the building’s mechanical system. The radiant heating and cooling system was projected to have more than a $2 million reduction in lifecycle costs compared to GSA’s traditional Variable Air Volume Systems. This cost reduction was based on an estimated annual energy savings of $228,000. In the two years since its completion, EGWW has boasted an average savings of $306,450 annually. This will result in a quicker payback than anticipated.

In addition to payback from the measures themselves, the project team used enhancement software for Revit to automate programming calculations and layouts (Onuma), space program checking (Solibri), and daylight modeling (Ecotect), as well as model‐integration clash detection software (Navisworks). The project team estimated that this delivery methodology resulted in accelerating the project by 10 months and saving American taxpayers more than $900,000 in the process. Today, the savings continue as the operations team leverages the BIM model to make refinements to the building’s systems.

Before starting design, project team performed extensive technical research on topics ranging from exterior shading and daylight, to thermal comfort, to occupant behavior in order to ensure the goals of EISA are meet. Working within the context of ARRA funding priorities, the project team defined a suite of inter-related conservation measures projected to exceed the minimum requirements of EISA. Since the primary policy goal of the Act is to increase energy independence by reducing dependence on limited energy resources, the team endeavored to achieve maximum energy use reduction within the guidelines of fiscal responsibility measured through life cycle cost analysis.

This predesign research included a façade optimization study done in two parts: a thermal analysis and a daylighting optimization analysis; a lighting design analysis that looked at savings and costs associated with incorporating various combinations of high performance equipment, thoughtful design strategies, and integration of daylighting and lighting controls; and a plug study that looked at average maximum equipment power density for office equipment, including discounts for diversity of occupancy and equipment usage patterns. In addition, the plug load study estimated how equipment power density changes through low occupancy periods of the business day, and during unoccupied hours.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Contracting Officer | Patrick | Brunner | General Services Administration Region 10 | Auburn, WA |

| Principal in Charge | Don | Eggleston | SERA Architects | Portland, OR |

| Design Excellence Architect | James | Cutler | Cutler Anderson Architects | Bainbridge Island, WA |

| Project Manager | Paul | Witherspoon | General Services Administration | Auburn, WA |

| Project Manager | Stuart | Colby | SERA Architects | Portland, OR |

| Project Manager | Jennifer | Taylor | SERA Architects | Portland, OR |

| Project Manager | Pat | Munter | Cutler Anderson Architects | Bainbridge Island, WA |

| Project Architect | James | Riley | SERA Architects | Portland, OR |

| Associate Principal | Lisa | Petterson | SERA Architects | Portland, OR |

| Project Manager | Suzanne | Blair | SERA Architects | Portland, OR |

| Job Captain | Gauri | Rajbaidya | SERA Architects | Portland, OR |

| Structural Engineer | Nathan | Infraffea | KPFF Consulting Engineers | Portland, OR |

| Structural Engineer | Erik | Kabusreiter | KPFF Consulting Engineers | Portland, OR |

| Commissioning Agent | Charles | Foreman | Glumac | Portland, OR |

| Mechanical Engineer | Joe | Tai | Stantec | San Francisco, CA |

| Electrical Engineer | Scott | Bevan | PAE Consulting Engineers | Portland, OR |

| Plumbing Design Principal | Jon | Gray | Interface Engineering | Portland, OR |

| Project Executive | Matthew | Braun | Howard S. Wright Construction | Portland, OR |

| Project Executive | Troy | Dickson | Howard S. Wright Construction | Portland, OR |

| Landscape Architect Project Manager | Michael | Moyers | PLACE | Portland, OR |

| Landscape Architect | Charles | Brucker | PLACE | Portland, OR |

This project transforms a generic concrete office building into a high-performance, environmentally responsive, comfortable place to work. There are a lot of existing, low-performance buildings out there that don’t contribute much to the urban fabric. In terms of impact, these are the buildings we need to address. This sets a great precedent for re-use and upgrade, and demonstrates the potential for creative, green reuse projects.