Genzyme Center

Project Overview

Genzyme Center is the corporate headquarters for a biotechnology company, with offices, an employee cafeteria, a library, gardens, training rooms, a conference center, cafes, and public retail space. Genzyme Center was created as a symbol of progress to represent a point of identification for the company, its employees, and visitors. The goal of the design was to develop a building from the inside out, from the individual working environment to the overall complex structure of the building. Largely due to the collaboration of the design team, developer, client, and construction team, this led to an environmentally friendly, highly communicative, and innovative signature building.

Design & Innovation

Predesign

The developer committed significant up-front resources to design at every stage in the development of Genzyme Center as a form of investigation and not just a veneer of packaging and styling. The commitment to this kind of "research" has had great demonstration value as the project has taken on a more definitive shape. This approach has been applied to all aspects of the project, from streetscape design to lighting and signage, as well as architectural and program refinement.

Starting with a strong urban plan, great importance was placed on introducing contemporary architecture through the vehicle of a series of invited international competitions. Thus, the design of the Genzyme Center was the result of an international design competition.

The selection criteria reflected the jury’s and sponsors’ ambition to push the design envelope. Great stress was laid not only on the performance of the individual building, but also on its ability to create a truly dynamic urban place in the context of the master plan and an exceptional environment for building’s occupants. An innovative design solution was sought that would meet the functional requirements of the program, but then move beyond, allowing for surprise, delight, and the unexpected.

The architect's design proposal strongly advocated an approach to the design that grew out from the work environment. In stark contrast to other, more highly articulated and well-formed design propositions for massing and skin, the veiled imagery of the scheme only began to hint at what the actual building might look like, but concentrated instead on a set of spatial relationships and environmental approaches that implied radical departures from the norm, but were still evolving and diagrammatic in form. In particular, the concepts presented attempted to break down the building volume and deal with the challenge of a large floorplate through a pattern of deep incisions of interior light and terraced internal openings.

The real issues and potential rewards inherent in this approach, even though it obviously presented great technical challenges, had great appeal to the client and the jury. The fact that the winning firm had completed projects in Europe that embodied some of the “green” environmental concepts presented was an important factor in establishing credibility, even though it was clearly understood that there would be a whole new set of code and compliance issues in a U.S. jurisdiction. In selecting a team, a deliberate decision was made by developer and client alike to embark on a commitment to sustainable design.

Design

Genzyme Center was planned by an international design team, for a client that has global reach. The proposal for the design competition presented a strong basis for the further development of the design of the building, including its environmental aspects. The client’s decision to pursue a LEED(R) rating was embraced by the entire design and construction team.

Green specifications allowed the consolidation of all “green” requirements related to the materials used in construction. These details were added into all the appropriate divisions of the specifications, serving as a guide to all those who bid on the various parts of the job. Samples and manufacturers' names were provided when possible to assist bidders, who were encouraged to provide alternatives that met the performance requirements. This allowed the project team to consider performance, cost, and “green” requirements in making final decisions.

The building’s exceptional performance is rooted in the early stages of its design and is the result of deliberate implementation of broad design strategies intended to achieve the most sustainable building possible. These strategies, such as the atrium concept, the natural daylight and ventilation systems, the exterior façade, the integrated building management system, the “green” construction specifications, and the filigree precast concrete system, among others, are critical to superior performance.

Regional/Community Design

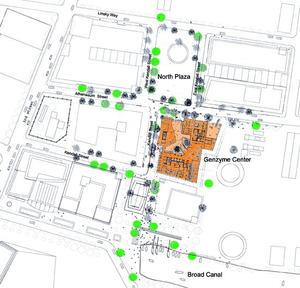

The building is located in the area generally known as Kendall Square, at the heart of a district framed by the MIT campus, the Charles River, and the East Cambridge neighborhood. The building is part of a ten-acre property that is one of the last large development parcels in Cambridge. Its former use as a coal gasification plant has left a challenging legacy of neighboring buildings that turn their backs to the site. Many of the adjoining properties are vacant or under-used lots. To the south, the site abuts a private drive located behind buildings fronting Main Street.

The Kendall Square area has undergone significant change in recent years and decades. It was a predominantly industrial area 40 years ago, lined with factories, utility operations, and parking lots, with the Cambridge Parkway as the only landscaped relief. With the redevelopment of key sites, such as the Cambridge side Galleria and now the Genzyme Center, Kendall Square has begun to emerge as a focal point for pedestrian life adjacent to the MIT campus and the subway transit stop. The development offers a highly urban, mixed-used community: biotech labs, offices, residential buildings, a four-star hotel, restaurants, theaters, and a broad range of retail uses will activate the site throughout the day. As a crossroads between a multitude of attractions and activities, the development including the Genzyme Center will evolve into a cultural, recreational, and retail hub.

Community Connection

The overall challenge of the master plan was to create a context for integration of a new neighborhood into the surrounding urban fabric. A number of adjacent streets provided excellent opportunities to connect with the neighborhood, much of which had been redeveloped over the past 15 years. Primary public access to the site is via Third Street, with secondary access from Second and Athenaeum Streets. The Kendall Square / MIT transit station on the MBTA Red Line is a five-minute walk from Genzyme Center. Over the past 20 years, the riverfront has evolved into an active recreation area. Future plans to link the Cambridge and Boston riverfronts through a series of interconnected parks and esplanades extending out to Boston harbor will further enhance the Center’s role as an access point to the riverfront.

To encourage alternatives to single occupant vehicles for commuting, Genzyme provides subsidies for public transit passes, a guaranteed-ride-home program, and carpool database services. In addition, the building has indoor bike storage with lockers and showers and additional bike storage in the garage. The garage has alternative fuel recharging stations for electric vehicles and has preferred carpool spaces.

Inherent in the developers’ commitment to redevelop this corner of Cambridge was their belief in the importance of a signature architectural design. The benefits enjoyed by the building’s occupants, its attractiveness to passersby, and the international buzz it has generated are evidence of the success of that philosophy. The developer has also made close to $1 million in affordable-housing-trust payments to the City of Cambridge, has donated surplus materials to community groups, will continue to institute traffic mitigation efforts, actively encourages the use of public transportation, and plans the construction of other public spaces, including gardens and a skating rink.

Land Use & Site Ecology

The Genzyme Center’s responsive site ecology relates primarily to using a remediated initial Brownfield site, utilizing existing infrastructure in redevelopment areas, reducing the heat-island effect caused by asphalt and other dark surfaces, and minimizing the building’s light pollution at night.

Construction tactics utilized also respond to site ecology by reducing disturbance to the site, maximizing open space, reducing erosion and stormwater runoff (which can pollute rivers), and protecting wetlands. Open space on the site, which exceeds city requirements by 50 percent, was planted with either native or adaptive plants and trees. All onsite parking of the Kendall Square development is below grade, eliminating the high albedo factor caused by asphalt parking lots. The roof of the building uses plant materials and a reflective surface to reduce heat absorption. This vegetated roof, along with a skylight rainwater collection system, reduces stormwater runoff by 25 percent. As part of a pollution prevention plan, filters were placed in the piping systems to reduce pollutant levels and stop soil erosion during construction. Light pollution is controlled by reflective lighting, controlling indoor lights, and shading with an automated blind system after dark.

Bioclimatic Design

Boston has a relatively humid summer climate, during which time the average relative humidity is 70%. Historic data on the coincidence of temperature and humidity was analyzed to establish the impact on the building services. The seasonal winds indicate predominantly westerly winds for Boston. However, the stronger winds associated with storm conditions tend to veer to the north. Annual weather data indicates annual precipitation of approximately 40 inches (1000mm). The monthly rainfall is very consistent, ranging on average from about 3” (80mm) in July to 4.5” (110mm) in November. The availability of sunshine and diffuse daylight in Boston is good. Weather records indicate that sunshine is recorded for more than half of the daylight hours. On average the cloud cover is 60% of the sky, indicating a good proportion of blue sky, almost independent of season. The average number of cloudy days per year is 163, or 44% of the year.

Energy efficiency was an important objective for the design team, in close collaboration with the owner and client. In parallel, our objective was to provide the users with a healthy work environment, allowing them a level of control over their immediate surroundings and visual and climatic connections to the interior and exterior of the building.

Among the innovations that optimize the building’s efficiency is an integrated building management system that controls all 30,000 automation points in the building—a level of complexity that rivals that of a bio/pharmaceutical manufacturing plant. From the roof heliostats down to the two motors on every window blind in every office, each point is programmed to respond to changes in the weather and in the interior environment, and to maximize natural light, bring in fresh air, and reduce reliance on conventional lighting and automated heating and air conditioning.

Light & Air

Superior environmental air quality was achieved through many design features. During construction, an indoor air quality management plan was designed and implemented. The building has strategically placed carbon dioxide monitors. All paints, coatings, sealants, and adhesives meet low-VOC standards. Carpets meet the Carpet & Rug Institute standards, and all composite woods are free of added urea formaldehyde. Chemical storage areas were designed with separate ventilation. Major entryways were designed with permanent grating systems to remove soil from foot traffic.

The building has operable windows and lighting controls for perimeter workspaces as well as permanent temperature and humidity monitors connected to the building management system. The building design meets the ASHRAE standards for thermal and humidity comfort. The light enhancement system provides sufficient natural light for at least 75% of work spaces where critical tasks are performed. Workspace layout and extensive use of glass on both interior and exterior walls permit views to the outside from all of the regularly occupied spaces. In addition, 18 indoor gardens and accessible outdoor patios further enhance occupants’ connection with the natural environment.

Creating an optimum working environment in the new Genzyme Center was identified as one of the key goals by the architects very early in the design process, primarily using natural daylighting measures and transparency. The Genzyme Center, by design, through its central 12-story atrium, maximizes natural light and views throughout the interior. The outer skin of the building was designed to maximize natural daylight exposure into the interior resulting in 75% of the office floor area being provided with a 2% daylight fraction. In addition, all workplaces have a direct visual contact with the outside.

Metrics

Water Cycle

Rainwater collected from the vegetated roof is used to supplement the water demand for the evaporative cooling towers, saving thousands of gallons of potable water annually. A second collection tank is fed from skylight runoff and irrigates the vegetated roof when the need is indicated by soil sensors. Overflow from the vegetated roof and from surface drains is filtered to remove solids before it is discharged from the site.

Water conservation features include efficient irrigation systems (including moisture sensors for both outdoor and indoor garden irrigation). Automated and low-flow faucets, waterless urinals, and dual-flush toilets installed in the building will reduce potable water usage by 32% below the standard established by the 1992 Energy Policy Act.

Once a client-funded soil-moisture sensor is installed on site, it will save 199,000 gallons each year, which is more than the building’s projected total (interior and exterior) irrigation water usage.

Energy Flows & Energy Future

The central heating and cooling systems are powered with steam from an adjacent power plant. The steam drives absorption chillers for cooling during the summer and is exchanged directly into heat for heating during the winter. This local energy cycle avoids distribution losses. As a result, peak summer electrical demand remains low and doesn't burden the aging electrical grid.

The building uses fan coil units to meet local heating or cooling loads in each space. This system delivers energy more efficiently by pumping water around the building rather than blowing air. Minimum fresh air is delivered to each space, but ventilation can be increased if carbon dioxide sensors register "stuffy" indoor air conditions. Fan coil units are automatically shut off when windows or doors are opened for natural ventilation.

Photo sensors and occupancy sensors detect conditions and dim overhead lights as needed. This results in significant energy savings and a personally controllable indoor environment. The daylight dimming system is expected to reduce lighting energy use by about 45%.

The natural light enhancement system utilizes a series of roof-mounted heliostats (mirrors) that track the sun's movement across the skylight to fixed mirrors. The fixed mirrors further reflect the light to a series of prismatic louvers located at the top of the atrium. The louvers also move with the sun’s path and elevation and reflect glaring, direct sunlight back to the mirrors, allowing diffuse light to enter the atrium. Once in the atrium, the light is further reflected to the floors by a system of hanging prismatic mobiles, reflective panels, and a reflective light wall on the inner surface of the atrium. On the outside glass walls, horizontal, reflective, motorized blinds reflect light up to reflective ceiling panels (the first two in the ceiling grid), which in turn reflect the light through glass inner walls deep into the floor plate.

One-third of the building’s façade is constructed as a double façade with a four-foot externally ventilated void. Operable blinds in the void block solar gains in the summer and vent them back outdoors before they enter the conditioned space. In the winter, the void is not ventilated and the blinds are open, making the double façade a warm buffer around the building. The remainder of the façade is double-glazed with low-emissivity coatings which, when combined with internal blinds, offer sufficient solar and thermal control.

The building has two photovoltaic arrays on the roof of the mechanical penthouses which generate 20-kW at peak output.

These energy-efficient features, along with efficient fans, motors, and equipment and an extensive building management system, reduce the projected overall energy cost for the building by about 41%. A third-party commissioning firm completed extensive building commissioning.

Energy Security

Steam-fired absorption chillers use heat, not electricity, as the primary fuel for generating chilled water for the building. The steam is distributed from a tertiary power generation cycle from the power plant next door. Steam lines are underutilized in the summer, and unused steam is often rejected. So, the use of this steam during the summer reduces electrical peak load demand and increases overall efficiency of the power plant. In addition, a small photovoltaic array on the roof produces 20 kW of power which contributes to reducing peak electrical demand on-site.

The building's outdoor ventilation systems continually monitor the quality of the indoor environment via the building’s management system and twelve carbon dioxide sensors. The input of fresh air varies to maintain "fresh" conditions within the building. Individual temperature control is enabled through the use of a four-pipe fan coil system located in smaller zones, offering work groups the ability to regulate the indoor environment.

Inside the building façade, louvered blinds continually adjust to the sun’s position to bounce natural light into the office space. These blinds have a control logic that can also be overridden locally to suit individual demands. The building’s primary artificial lighting system adjusts in light output depending on the availability of natural light in the offices. On hot summer days, the electrical demand for lighting is reduced from 365 kW to 260 kW.

All of the electricity supplied to the building has been supplemented (or replaced) by Green-e certified renewable sources.

Metrics

Materials & Construction

Genzyme Center is framed with filigree slab concrete, an unusual and challenging application for this material, in a building with irregular, non-standard floor plans. The concrete structure substantially increased the thermal efficiency of the finished building. But the inherent strength of the filigree slabs also reduces the need for reinforcing steel. By using foam fillers in the panels, the overall structural weight was reduced, thus requiring fewer concrete piles and reducing the foundation elements. In total, the contractor used 386 fewer tons of steel reinforcing bar and 2,552 fewer cubic yards of concrete than would otherwise have been needed.

Specifying a customized 12” upturned edge on the filigree also allowed for the incorporation of precast filigree slabs, saving more than 2,600 sheets of plywood forms and construction time. In addition, since a conventional cast-in-place building of this size would typically require 357 gallons of release agent for stripping the wood forms, the use of the filigree significantly reduced the release of VOCs into the environment at the factory and on-site.

Several features and programs were incorporated to preserve natural resources. More than 500 ft2 of area within the building is devoted to the storage of recyclables collected as part of the building’s recycling program. By the LEED calculation method, 23% of the building materials in aggregate are recycled material. More that 50% of the materials were manufactured locally, and nearly 90% of the wood products used were FSC certified.

Diversion of Construction & Demolition Waste

A construction waste management plan was developed and implemented that resulted in the recycling or reuse of 93% of construction waste.

The construction process was challenged by the mandate that base building and tenant fit-out construction be carried out almost simultaneously. The typical divisions between architect, owner, contractor, and tenant had to be dissolved to accommodate European construction techniques on an American fast-track schedule. An exceptionally efficient team effort allowed more than 100 change orders to be requested by the client, approved by the architects and the developer, and incorporated into the construction process without one extra day being added to the schedule.

One of the most critical pieces of the sustainability puzzle, in construction terms, was the decision to use a new kind of concrete-slab construction, rarely used in office buildings, called a “Filigree Wideslab,” which has many green benefits. It is a composite system of 2-1/2” thick pre-stressed, precast planks that initially act as formwork before their composite behaviors kick in. Depending on the structural requirements, varying depths of traditional reinforced cast-in-place concrete are then joined together by welded wire trusses embedded inside. Polystyrene void formers eliminate unnecessary zones of concrete, making the slab much lighter. The environmental benefits of this system include the reduced amount of concrete, steel, and release agents, and the thermal mass of the concrete.

Long Life, Loose Fit

The developer has made every effort to ensure that each component of their new urban community at Kendall Square is of world-class quality. They believe that excellent contemporary architecture is an essential part of a durable urban environment and have acted on this belief in selecting the design team for the Genzyme Center. Interior environments in the workplace and their flexibility today are more important than ever. This continues the rationale used throughout the Genzyme Center. Individuals are given the freedom to modify their environment. People should have the opportunity to adapt it to their own needs within a framework that allows an overall standard of quality to be maintained. This flexibility also allows the opportunity to join two or more workstations together to form a creative team, enhancing communication. This allows a wide range of choices, from privacy to communication, achieving the design goal.

In keeping with its respect for the individual, the client’s employees were able to choose the chair, file cabinets, and other components for their offices or cubicles. Chairs, tables and desks are all height adjustable. Office cubicles can be easily reconfigured for maximum spatial flexibility. Most employees have wall switches that allow manual over-rides of lighting and temperature controls of the building. The operable windows not only allow employees to control indoor air intake, but vary the exterior building in design, color, material, and proportion.

Collective Wisdom & Feedback Loops

Operations/Maintenance

An extensive operations and maintenance user manual was developed for the project. The manual, in electronic form, covers all areas of building materials, equipment, and systems. Divided into 18 chapters, it covers information on the following: earthwork, concrete, masonry, steel, metals, millwork, roofing, insulation, curtainwall, doors, hardware, ceiling panels, flooring, painting, audio-visual equipment, building maintenance systems, blind systems, interior plants, fire protection, elevators, HVAC, electrical, PV system, lighting, emergency power, building management system and green building elements. Each section describes what is in the building and contains Web site addresses and references to manufacturers of the materials, equipment, and products in the building.

Commissioning

An independent commissioning agent was hired to review building systems, provide a commissioning plan, monitor the installation of equipment, and conduct a final operational survey. The agent completed plan and submittal reviews and provided a manual that contained information for re-commissioning to be conducted during the first year of occupancy. The agent also verified installation, performance, training, and operation of key building equipment and systems and submitted a final commissioning report.

Post-Occupancy

The independent commissioning agent designed and executed a measurement and verification plan prior to building occupancy. The plan consisted of verifying the operation of lighting systems, motors, drives, chillers, water systems, heat recovery equipment, and controls. Air-distribution systems, process-energy systems, and irrigation systems were also monitored and their performance was measured. The entire building underwent a two-week fresh-air flush-out period prior to occupancy.

Other Information

A 20-kW photovoltaic system was partially funded by a grant from the Massachusetts Renewable Energy Trust.

The greening process in our design makes good sense all around. First, it offers direct operating savings. There is also a growing body of evidence that supports the theory that high-performance buildings are beneficial to employee health and productivity. While these costs and benefits are still in development, the potential for savings is significant. One report indicates that annual personnel costs vary from $300 to $500 per square foot. Therefore, a 1% increase in efficiency could be worth $3 to $5 per square foot. For Genzyme, this could average $1,040,000 per year in personnel efficiency alone.

It has been recorded that companies who provide a good working environment report a considerable drop in absenteeism, which enhances the productivity figure above. People value a direct connection to the outdoors. This is supported by European blue-green laws coming, whereby all employees are entitled to a view of the sky and vegetation. The role of daylight is a key factor in the design, as it has a positive effect on the productivity of the workforce. A number of studies also point out that the problem stated above is often also a consequence of uncomfortable surroundings, which include furniture ergonomics. This was evaluated and brought into the design of the furniture as a means for the employees to create and modify their own work environment.

There are many aspects to the greening process, and the success of the Genzyme building will be recorded in its LEED rating and its future "real life" use.

The major lesson we learned is that by paying attention to the individual, we can do greater good for the whole. The approach to this building was to design "from the inside out”—to look at the needs of the individual employee as he or she relates to the company, the workspace, colleagues, and the environment. With that in mind, the design team then continued to enlarge the focus to the department, company, building, development, city, environment, etc. With a micro/macro view, every decision—from building envelopes to mailing envelopes—is guided by a responsibility to the environment.

There are many “un-programmed” spaces throughout the building—including coffee bars, interior gardens, and seating areas—that are available for employee interaction. As a result, private offices are smaller. This has been a very successful situation for communication and work productivity.

This was a complex project with an international team: German designers; an American developer, client, and contractor; England-based structural engineers; and Austrian lighting consultant. All looked at every aspect of the project to go as far as possible. The result is a building that is comfortable, beautiful, unusual, and joyful.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Architect (Executive architect – base building) | House & Robertson Architects | Los Angeles, CA | ||

| Architect (Executive architect – tenant improvement) | Next Phase Studios | Boston, MA | ||

| MEP and environmental consultant | Buro | Happold | New York, NY | |

| Lighting consultant | Bartenbach LichtLabor | Aldrans, Innsbruck Austria | ||

| Interior gardens consultant | LOG ID Solararchitectur | Tubingen, Germany | ||

| Landscape architect | Michael Van Valkenburgh Associates | Cambridge, MA | ||

| Contractor | Turner Construction Company | Boston, MA |