Research Support Facility

Project Overview

From its inception, the Department of Energy's (DOE) Research Support Facility (RSF) at the National Renewable Energy Laboratory (NREL) was designed to be a world-changing building. With the goal of creating the largest commercial net-zero energy structure in the country, the building is meant to serve as a blueprint for a net-zero energy future and influence others in the building industry to pursue low energy and net-zero energy performance. This building is meant to further the DOE and NREL's long-term mission.

The RSF is a large-scale office building housing more than 800 people who support and conduct the important research work at this national laboratory. The building also houses a data center that serves the entire NREL campus. NREL and DOE's goal is to transform innovative research in renewable energy and energy efficiency into market-viable technologies and practices. This building serves as an example of these ideas and a living laboratory for the staff of the RSF to learn from and work by. The resulting project is one of the most energy-efficient buildings in the world, providing a high-performance workplace and aiming at operating at net-zero energy on an annual basis.

Environmental Aspects

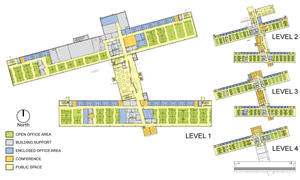

As our client at NREL notably said, "every design decision has an energy impact." The net-zero energy goal for this project amplified every design decision and explicitly shaped the building and resulted in a positive impact on the program and functionality of the building. The building is a simple architectural response to the climate, site, and ecology that envelop it and the desire for a flexible, high-performance workplace within. Many of the integrated passive design strategies, such as daylighting and natural ventilation, strongly support both energy performance and human performance. The form of the building is driven by energy, with its long and narrow office wings connected by a central spine, forming an "H" shape. In fact, the building section was the first drawing sketched to understand how to harness passive energy.

The energy-driven form also facilitated significant building program and functional benefits. The open office plan resulted in a higher-density workplace, reducing the building footprint per person. The "H" shape provided secure separation between staff work areas in the office wings and collaborative public meeting spaces in the central collector. This shape also provided two exterior courtyards, which have become popular amenities.

Owner & Occupancy

Owned and occupied by Department of Energy's National Renewable Energy Laboratory, Federal government

Typically occupied by 822 people, 50 hours per person per week; and 60 visitors per week, 2 hours per visitor per week

Design & Innovation

As our client at NREL notably said, "every design decision has an energy impact." The net-zero energy goal for this project amplified every design decision and explicitly shaped the building and resulted in a positive impact on the program and functionality of the building. The building is a simple architectural response to the climate, site, and ecology that envelop it and the desire for a flexible, high-performance workplace within. Many of the integrated passive design strategies, such as daylighting and natural ventilation, strongly support both energy performance and human performance. The form of the building is driven by energy, with its long and narrow office wings connected by a central spine, forming an "H" shape. In fact, the building section was the first drawing sketched to understand how to harness passive energy.

The energy-driven form also facilitated significant building program and functional benefits. The open office plan resulted in a higher-density workplace, reducing the building footprint per person. The "H" shape provided secure separation between staff work areas in the office wings and collaborative public meeting spaces in the central collector. This shape also provided two exterior courtyards, which have become popular amenities.

Regional/Community Design

Integrated into an existing campus, the Research Support Facility enables previously separated staff to come together in one location. It creates outdoor pedestrian spaces designed to entice employees to utilize courtyards. Shuttles, city buses, bike parking, and minimized on-site parking opportunities encourage employees to use alternate methods of transportation. In fact, the bike parking is regularly full and in high demand.

Responsible to neighbors, the campus is careful to protect the existing wildlife and the community life surrounding this new facility. The community and local residents were represented, and their concerns were addressed, throughout the design process. The building height is kept lower than zoning codes allow to respond to the local community’s desire to maintain view corridors. The project team and the owner worked with the county to maintain trail access through the federal campus. Part of the project included the dedication of land area on the campus’s south table mountain mesa as permanent open space to extend an existing conservation easement.

In addition to its community impact, the Research Support Facility on the NREL campus is an important regional facility and part of Colorado’s identity as a leader in sustainable and renewable energy.

Land Use & Site Ecology

The building and site are part of the overall ecosystem and are rooted with a strong sense of place. The building is formed around the forces and natural resources of the climate and the site. The building responds not only to sun and wind but also to the natural lay of the land and the context of the existing campus. The landscape design paid particular attention to natural stormwater management techniques, open space preservation, permeable paving systems, native landscape integration, use of high-albedo pavements, and the innovative use of onsite excavated rock for gabion walls.

The integration of the landscaping has already proven to be a successful creation of habitat, with frequent visits from a local herd of deer and other wildlife. The site is also an exemplary habitat for people and creates a natural, beautiful and comfortable exterior space to enjoy while strongly contributing to the overall campus master plan. The Research Support Facility has been selected as one among 150 projects to take part in an international pilot project program to evaluate the new Sustainable Sites Initiative (SITES) rating system for sustainable landscapes

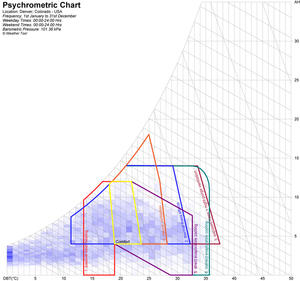

Bioclimatic Design

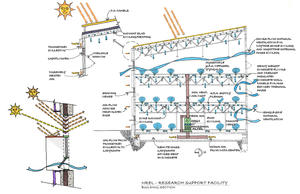

The building is shaped around the climate to optimize passive energy strategies. The 60' wide section for the main office wings was driven by the objective to daylight and naturally ventilate the main office wings. The narrow footprint results in two long office wings oriented along the east/west axis and linked by a central connector space consisting of the lobby and conference facilities.

The solar geometry of the site dictated the shading and daylighting strategies. The seasonal and diurnal temperature changes of the climate influence the integration of thermal mass and night-flush capability in the building interior and in the thermal labyrinth in the crawlspace. The geometry of the building was studied in a wind tunnel to fine-tune the effectiveness of the operable windows and cross ventilation, as well as pedestrian comfort in the exterior courtyards.

This building begins to hum as soon as the sun hits it, which is ideal given the number of sunny days in Colorado. The building creates its own electricity, heats its own ventilation air with a transpired solar collector, and shades all windows during the summer while providing an exemplary daylit space all year round.

Light & Air

The project utilizes strategies that leverage light and air to increase energy performance and improve workplace performance. Daylighting is the keystone strategy for the project because it significantly impacts lighting energy, cooling energy, and productivity.

The building massing and window design optimize control and harvesting of daylight. Virtually every workspace in the main office wings is daylit. Overall, 92% of all regularly occupied spaces are daylit. Air quality is enhanced by increasing the amount of outside air delivered to spaces. All office spaces have 100% outside ventilation air delivered through an underfloor air distribution system. The ventilation system is decoupled from the space conditioning system, saving significant energy.

The building also has operable windows and is designed for effective cross-ventilation by using a narrow 60' deep floor plate for the main office wings. Effectively all spaces in the open office area, as well as the conference rooms and lobby spaces in the central connector space between the two main office wings, have excellent access to natural ventilation. A small icon appears on everyone’s computer informing them when it is an appropriate time to open a window.

Metrics

Water Cycle

The project achieves high levels of water conservation while still complying with Colorado water laws that limit water reuse strategies. Although rainwater cannot be captured, per Colorado water laws, the project still used the roof area of the project to determine a water use budget. In an average year, a little more than 797,000 gallons of water falls on the roof of the building. The building and site water uses are modeled at just over 791,000 gallons per year. A combination of highly efficient plumbing fixtures, native and adaptive landscaping, and drip irrigation with a satellite-based smart irrigation controller were used to reduce building water use by 55% and irrigation water use by 84% compared to LEED baselines.

The site design for the project works in tune with the existing natural hydrology. The strategies include a series of rain gardens for roof drainage collection, porous paving within the courtyards, and bioswales to connect water collection points to the existing natural arroyo system of the campus. This allows precipitation to infiltrate the soil and take on patterns of drainage consistent with its pre-developed hydrology.

Energy Flows & Energy Future

Achieving net-zero energy requires optimization and integration of all the energy flows and systems of the building with a reliance on many passive energy strategies. Lighting is an integrated system of daylighting, daylight control systems, occupancy controls, and high-efficiency lighting.

Thermal comfort is addressed using an integrated system of thermal mass, radiant slabs, night purging, and natural ventilation. Heating in particular takes a whole-systems approach to energy conservation. The building includes a large thermal labyrinth under the two main office wings. The labyrinth can store heat from the transpired solar collectors located on the south building facades. This heat is used to passively temper the ventilation air during the heating season. The labyrinth also serves as a thermal sink for reject heat from the data center, dramatically lowering the cooling load of the data center year round.

The building’s extremely detailed energy model predicts an energy use intensity of 33 kBtu/ft2/year. The onsite photovoltaic system is sized to meet net-zero site energy at an EUI of 35 kBtu/ft2/year. The onsite PV coupled with the passive strategies, such as thermal mass, natural ventilation, and daylighting, are also strategies for passive survivability in the event of a power outage.

Metrics

Materials & Construction

The incorporation of passive design features led to the narrow building footprint and to a correspondingly high quantity of exterior envelope. One of the largest challenges of the project was to design and construct the exterior envelope within the overall budget of the project.

One key strategy employed was the use of modular construction. The exterior wall is composed of insulated precast wall panels with finished interior and exterior surfaces. The other key strategy was to optimize the amount of glass and therefore not over-glaze the main office wings. The optimization of the glazing allowed cost control and solar gain control while maintaining fully daylit office spaces.

The material choices for the building were driven by the desire to have flexible and durable materials with low health impacts and reduced resource consumption. Construction waste diversion (75%), low-emitting materials, recycled-content materials (34%), regional materials (13%) and certified wood materials (59%) were all incorporated based on LEED compliance. Several highly visible, innovative materials were also incorporated into the project, including the use of reclaimed natural gas pipe as structural columns and beetle kill pine used as decorative wall elements throughout and as a multi-story feature wall in the lobby.

Long Life, Loose Fit

Flexibility and adaptability are key sustainable design features but also very important workplace design strategies. The 60' deep office wings have column-free interiors, and the cores are small and decentralized to allow the basic core and shell of the building to have tremendous flexibility.

The workplace is designed with modular components, such as a raised floor, demountable walls, and modular furniture solutions. These systems make the workplace highly adaptable over time. These systems also created a very efficient space plan that allows the owner to add more occupants to the building with less overall building area.

The building is designed for a long service life of 50 years or longer. The main exterior wall finishes are highly durable, long-life materials, including architecturally finished precast concrete wall panels and natural zinc panels. The building is also designed to be expandable. In fact, a 138,000 ft2 extension to the building is already under way and is taking full advantage of the lessons learned from the original building. The building expansion is predicted to be 17% more energy efficient at a cost that is $13 lower per square foot than the cost for the original building.

Collective Wisdom & Feedback Loops

All building occupants and visitors can see in real time a summary of daily and annual energy use, broken down by end uses and total energy on two large video displays in the lobby. This is a visual reminder of the owner’s long-term goal of net-zero-energy operation, but also reinforces the office culture around a high-performance and low-energy workplace.

However, the reach of the energy story goes far beyond its own walls. One of the owner’s primary objectives for the project is to create a building that can serve as a model to the industry for achieving net-zero-energy performance in large-scale commercial buildings. The design-build team and owner team are actively engaged in using the project as a case study to educate building professionals and building owners across the nation. These forums include regional and national conferences, building tours, workshops, videos, and industry publications. The delivery team and the owner are also fully monitoring the building performance and conducting post-occupancy evaluations and are sharing lessons learned with the industry.

Other Information

The Research Support Facility was delivered through a national design competition and breakthrough DOE performance-based procurement process. It called for unprecedented collaboration by owners, designers, engineers, and contractors to achieve what had never been attempted before.

In this design-build, fast-track, multi-bid proposal, DOE/NREL set forth a list of 26 tiered project performance objectives categorized as “Mission Critical,” “Highly Desirable,” and “If Possible.” The delivery team chose to design a structure that would meet all 26 objectives, including the desire to use a net-zero-energy design approach, for the firm fixed price of $64 million. The project contract compensated for the additional risks taken by the team by offering a sizeable award incentive distributed at project milestones based on the team’s performance.

The photovoltaic systems totaling approximately 1.6MW for the project are not included in the $64 million total project costs. The PV on the roof of the RSF was procured using a Power Purchase Agreement. The remaining PV for the project was purchased using ARRA funds. These panels are scheduled to be installed in the fall of 2011 as shading canopies over the RSF’s parking garage.

Predesign

The pre-design and concept design phase of the project began with a national design competition that was part of DOE’s innovative performance-based procurement method. The delivery team started the four-month competition phase with a multi-day design charrette involving all the integrated disciplines that focused on design solutions addressing the LEED Platinum requirement and the owner’s desire for a net-zero-energy building—while meeting the functional, programmatic and cost requirements of the project. The design charrette began with the development of a simple energy model to begin testing design strategies and helped the team quickly move toward a solution that was deeply passive, with a form and exterior envelope that was responsive to the climate, used water-based radiant heating and cooling systems, and decoupled the ventilation air from space conditioning. The resulting design concept proved to be highly integrated and changed little from what was ultimately constructed.

Design

The emphasis on innovation and integration that started in the competition phase continued through the design process. The delivery team refined and developed the various systems and passive strategies into a highly integrated singular solution. The design process was streamlined by the use of BIM across the design and construction team. Energy modeling in addition to simulations for daylighting, natural ventilation, thermal mass and the transpired solar collector continued to develop in detail, staying true to the design and serving as a continued performance evaluation tool for both the delivery team and the owner.

Construction

With the design-build process and fast-track schedule, the design and construction activities overlapped and were highly integrated. With the full delivery team aligned around the project objectives, including the goal for net-zero energy, we were able to effectively manage costs and risks to ensure project success. The energy modeling process continued through construction, resulting in an as-built energy model that documents the building as it was ultimately constructed.

Operations/Maintenance

One of the most remarkable aspects of the entire delivery process is that the owner and the delivery team have been able to close the gap between design intent and actual operation. The building is metered and sub-metered by energy end uses, so that the energy performance can be directly verified against the energy model. The model inputs regarding schedule and building operations were developed collaboratively between the delivery team and the owner. In fact, the model and its embedded design intent now serve as a guide for the owner’s facility management staff in terms of operating the building and managing energy use.

One of the lessons learned in the project is that the metering of the project should also be commissioned. While many end-use sub-meters have been working reliably, a few are still being verified and corrected. The delivery team and the owner are excited by the preliminary results. Although we are still waiting to develop reliable monthly whole-building energy data, the end-use sub-meters that have been verified are showing better than modeled results.

Commissioning

The building was fully commissioned, satisfying the LEED prerequisite for fundamental commissioning and the LEED credit for enhanced commissioning.

Post-Occupancy

The commissioning agent was retained to provide measurement & verification services for the project, and these services are currently under way. In addition, post-occupancy evaluations will be conducted. There is also a plan for deeper research and evaluation on how the occupant behaviors are interacting with the various passive energy systems and the net-zero energy goal.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Owner/developer (Director, Public Relations) | Kerry | Masson | National Renewable Energy Laboratory | Golden, CO |

| Architect (Lead Designer) | Craig | Randock | RNL | Denver, CO |

| Architect (Project Manager) | Michael | Simpson | RNL | Denver, CO |

| Architect (Director of Sustainability) | Tom | Hootman | RNL | Denver, CO |

| Commissioning agent | Michael | Holtz | Architectural Energy Corporation | Boulder, CO |

| Contractor | Byron | Haselden | Haselden Construction, LLC | Centennial, CO |

| Structural engineer | Brant | Lahnert | KL&A Engineering | Golden, CO |

| Civil engineer | Duane | Jansen | Martin/Martin | Lakewood, CO |

| Lighting designer | Rachel | Petro | RNL | Denver, CO |

| Landscape architect | Marc | Stutzman | RNL | Denver, CO |

| Interior designer (Interior Design Project Manager) | Wendy | Weiskopf | RNL | Denver, CO |

| Mechanical engineer | John | Andary | Stantec Consulting | San Francisco, CA |

| Electrical engineer | David | Knoll | Santec Consulting | Sacramento, CA |

| Energy consultant | David | Okada | Santec Consulting | San Francisco, CA |

| Plumbing engineer | David | Okada | Santec Consulting | San Francisco, CA |

| Information Technology | Howard | Finegold | Technology Plus, Inc. | Aurora, CO |