Steinhude Sea Recreation Facility

Project Overview

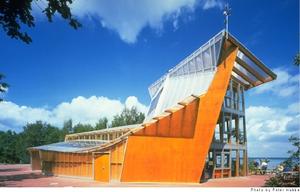

This small recreation facility building is located on an island at the south shore of the Steinhude Sea. The island ecosystem consists of a beach area, green fields, a nature walk, a children's play area, and a bird sanctuary. The facility accommodates, with minimal ecological impact, a cafe, lifeguard facilities, a boathouse, storage space, public toilets and showers, and an exhibition area and observation deck. This project aesthetically synthesizes the island's recreation and vacation culture.

Design & Innovation

Predesign

This project was conceived as an amenity to EXPO 2000 visitors to the rural region of the Steinhude Sea, north of Hannover, Germany. The theme for EXPO 2000, "Man, Nature, Environment," led to the goal of an artistically intriguing structure that is fully self-sustaining with minimal impact on the surrounding ecosystem.

Design

The team of an American architect, German engineers, local utility company representatives, and city officials developed a strategy of fully integrating sustainability concerns from conceptual design through to the construction fabrication process.

Regional/Community Design

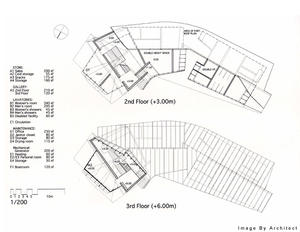

The building footprint covers approximately 2,200 square feet of an 11.4-acre island. The site has no on-site parking and minimal paved areas for access by emergency personnel vehicles only.

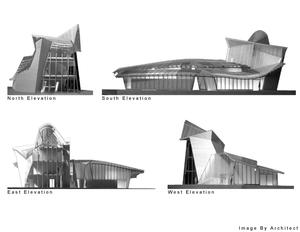

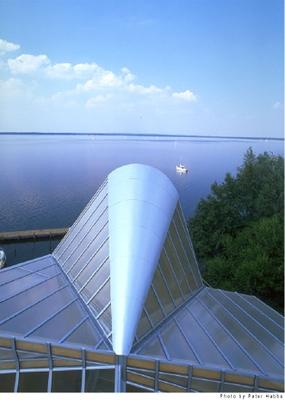

The project serves as symbol for the community in every season. Its translucent skin, designed for daylighting and power generation, also serves as a lantern when viewed from the sea. During both summer sailing season and winter wind-surfing on the frozen lakebed, the building form is an icon for relaxation and community socialization.

As an automobile-free island, all occupants arrive by foot, bicycle, or boat. The pier associated with the project has its own fleet of eight photovoltaic-powered electric boats that are available for tours of the lake and neighboring attractions. An observation deck contains descriptive panoramic graphics of distant viewpoints and community features.

Metrics

Land Use & Site Ecology

Located off the south shore of the Steinhude Sea in north-central Germany is the 11.4-acre (46,000 m2) island known as Badeinsel (Bath Island), connected to the mainland by bridge. Lining the mainland shore are marinas and residential structures, while the island is a nature preserve accessible for public recreation. The new 3,057-square-foot (284 m2) facility accommodates public services and amenities with minimal ecological impact.

Approximately 80% of the site fits the description of the on-site ecosystem. The estimated precipitation managed on site is estimated at 95%.

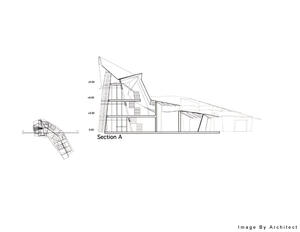

The project was sited on the leeward side of a constructed jetty, which protects the island edge from wind and current-based erosion. The site was also selected due to its proximity to deeper water for boat access and its safe distance from the bird sanctuary. The building rests delicately in the landscape with its curving roofline appearing to emerge from the topography.

The low load capacity of the bridge to the mainland meant that getting heavy equipment to the island would be difficult and the delicate nature of the island-edge condition and suggested that the presence of such equipment would be very detrimental to the site. Therefore, the decision was made to fabricate the building in a factory on the mainland and bring it to the island as a panelized system that could be erected from barge-mounted cranes at the shore edge.

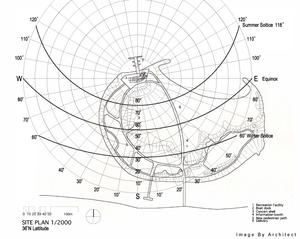

Bioclimatic Design

Energy self-sufficiency has been accomplished by photovoltaic panels, solar hot water collectors, a seed-oil fueled cogeneration microturbine, daylighting, natural ventilation, passive solar design, building automation, and high-performance materials. These systems provide complete lighting and power needs for the building, recharge a fleet of eight photovoltaic-powered boats, and also produce excess electricity to sell back to the utility grid.

Other sustainability practices incorporated into the design include graywater and harvested water systems, green materials, and waste reduction.

The integration of solar and renewable ideas has led to a building that is a joy to its users.

Light & Air

The interior of this very contemporary building gestures to the history of wood construction and half-timber framing in the region. It is oriented to maximize views to the seashore and other community destinations such as the Wilhemstein Island and its historic castle.

An interior dominated by diffuse natural light and natural cross ventilation creates a healthy indoor environment, while the creative use of solar energy technologies contribute to visually striking patterns of light and shadow.

The building has spaces that provide soothing relief from the hot summer sun and other spaces that feel like the German tradition of "winter garten," flooded with light and warmth in colder weather.

Water Cycle

A graywater system supplies the public and staff toilet facilities. The collection system occurs through the terraces surrounding the building. The un-guttered roofs also supply the graywater collector. Waste and wastewater is piped below the pedestrian bridge back to the sewer system on the mainland to avoid pollution of the high water table or the adjacent lake water. Paved access areas to the building use interlocking concrete paving units with sand setting, allowing water permeation and minimal runoff.

Energy Flows & Energy Future

Through the close collaboration of architect, engineer, and utility company, the solar and sustainable energy components collectively produce 60,000 kilowatt hours of energy per year and provide the equivalent of an annual 60,000 kilograms in carbon dioxide emissions reduction.

This project is not only energy self-sufficient but also recharges a fleet of eight solar-powered boats and generates surplus power to sell back to the utility grid. The photovoltaic panels distribute cells within an insulated glazing unit, allowing the photovoltaic panels to serve as roof, daylight provider, and electricity generator in one application. The panels (with inverter and batteries) provide all of the building's lighting needs.

Domestic hot water needs are met by a solar hot water collection system (cylindrical glass-tube array within a dual glazed frame). The glass tubes also contribute to daylighting and have an educational exhibit quality, whether viewed from interior or exterior.

A cogeneration microturbine fueled by rapeseed oil provides backup power for extended cloudy days and supplemental power for peak loads associated with the cafe equipment. High standards of energy conservation, including natural ventilation, daylighting, thermal-mass storage, and building automation, reduce power consumption.

Building materials selected for high thermal performance includes aluminum mullions with integrated thermal break, insulated glazing, insulated polycarbonate panels, and mineral-fiber insulation. Portions of the building are zoned primarily for summer use and are not mechanically climate controlled.

Metrics

Materials & Construction

The factory prefabrication and panelized assembly of this building allowed minimal waste to be generated while creating a highly customized building. The contractor, whose primary business is in panelized housing, was able to translate the architect's disciplined modular dimensions into fabrication processes. Even the photovoltaic panel size was selected to match a conventional framing dimension so that there were no sub-framing requirements for secondary components. Stairs were prefabricated as well, taking advantage of economy of means available in the factory setting.

Major construction materials consist of wood, translucent wall panels and windows, and metal stairs. All wood used, including wood studs, plywood, glue-laminated beams, and timber framing, was certified reforested wood from central European sources. Recyclable materials used include aluminum and glass curtain wall, concrete floor pavers, mineral-fiber insulation and polycarbonate translucent panels.

Design for Materials Use Reduction

-Consider the use of structural materials that do not require application of finish layers

-Consider exposing structural materials as finished surfaces

Job Site Recycling

-Use modular or prefab construction

Materials and Wildlife Habitat

-Use wood products from independently certified, well-managed forests for rough carpentry

-Use wood products from independently certified, well-managed forests for finish carpentry

Long Life, Loose Fit

This facility is a specific design response to the limited needs of lifeguards and island visitors. No other development is allowed on the island; therefore flexibility for change of occupancy was not a design criterion. A second phase was master-planned in case of future expansion requirements for emergency-services personnel.

Other Information

The local utility company, EMR (Electrizitatswerk Minden-Ravensberg), provided financial assistance by acknowledging the lifecycle energy returns and financing the additional cost of energy-related "active" components (cogeneration microturbine, solar hot water collectors, energy analysis and building automation computer system, etc.). They also wrote the grant application that won the SOLTEC award and paid for the photovoltaic system.

The first lesson was the importance of letting minor dimensional requirements govern the planning module so that multiple systems come together with minimal waste and minimal customization of details.

The second big lesson was to find the right construction partner with the technical ability to read the architect's 3-dimensional database and the motivation to interpret it correctly. Note that this project had no "construction documents phase." Rather, it was produced from sophisticated "shop drawings" of the entire building from the architect's extremely detailed Form Z computer files.

Lastly, we learned there is no substitution for teamwork with the local utility company and the resources, such as grant writers and energy consultants, that they bring to a project.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Architect | Jurgen | Beinke | Archimedes GmbH | Bad Oeynhausen, Germany |

| Architect | Stefan | Hoffmann | Archimedes GmbH | Bad Oeynhausen, Germany |

| Architect | Corinna | Hohkamp | Archimedes GmbH | Bad Oeynhausen, Germany |

| Architect (Executive architect) | Hartwig | Rullkotter, AKNW | Archimedes GmbH | Bad Oeynhausen, Germany |

| Mechanical engineer | HV Objektbau | |||

| Contractor | HV Objektbau | |||

| Electrical Engineer | HV Objektbau | |||

| Structural engineer | IHV Objektbau, Dipl.-Ing. Hubert Wemheuer, Prufingenieur fur Baustatik | |||

| Energy consultant | Jurgen | Kotter | ||

| Architect | Wes | Adachi | Randall Stout Architects | Los Angeles, CA |

| Architect | Richard | Claridge | Randall Stout Architects | Los Angeles, CA |

| Architect | Sebastian | Kaempf | Randall Stout Architects | Los Angeles, CA |

| Architect | Stephanie | Kaindl | Randall Stout Architects | Los Angeles, CA |

| Architect (Director of communications) | Yukio | Okeda | Randall Stout Architects | Los Angeles, CA |

| Architect (Design architect) | Randall | Stout | Randall Stout Architects | Los Angeles, CA |

| Architect | Freidrich | Tuczec | Randall Stout Architects | Los Angeles, CA |

| Architect | Timothy | Williams | Randall Stout Architects | Los Angeles, CA |