Yale Sculpture Building and Gallery

Project Overview

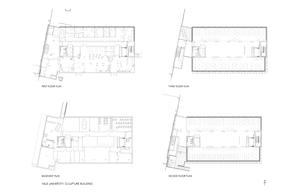

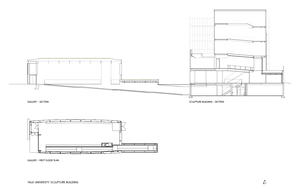

The Yale Sculpture Building and Gallery complex includes three new buildings: the four-story Sculpture Building, the one-story storefront gallery, and a four-story parking garage. The Gallery and parking structure reestablish the block's perimeter, while the Sculpture Building acts as a lantern, illuminating the core.

The Sculpture Building provides three floors of individual and group studios above a ground floor and basement of classrooms, machine shops, and administrative spaces. The Gallery is used for year-end shows, ongoing exhibitions, and lectures. The parking garage features retail, restaurant, and Yale Security Services space and will rent out space on the ground floor. The Sculpture Building and Gallery comprise 62,000 ft2; with the parking structure (including retail space) the total project floor area is 197,000 ft2.

Design & Innovation

Located on a former brownfield site, the project reclaims a formerly derelict parking lot for the community. Five bus lines stop within walking distance of the site, and the project features bicycle stalls and showers.

Waterless urinals, dual-flush toilets, and low-flow faucets reduce water use, and rainwater collected from the roof of the Sculpture Building and surrounding landscape is used to flush toilets, eliminating the use of potable water for sewage transfer.

The project team oriented the Sculpture Building to minimize eastern exposure and almost eliminate western exposure. South-facing windows were designed to provide daylighting without glare in the summer and to provide daylighting in addition to heat gain in the winter.

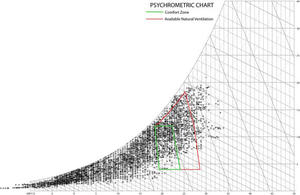

Exposed concrete slabs and high-performance insulation reduce demand on the heating and cooling systems. Operable windows allow the building to be naturally ventilated in spring and fall, and a displacement ventilation system supplies fresh air at low velocities and higher-than-usual temperatures. The workshops are equipped with comprehensive exhaust systems that adjust to the number of machines running.

The Sculpture Building's interior spaces feature utilitarian, unfinished surfaces with exposed steel structures. The sunscreens on the Gallery are made of reclaimed cedar, and the project team sought out regional materials.

Regional/Community Design

While much of Yale University remains cloistered in quadrangles that exclude the citizens of New Haven, the Sculpture Building and Gallery invert those historic patterns. Pathways traverse the site, drawing pedestrians into the new complex. The east-west path is planned as an outdoor sculpture garden that connects all the way back to Louis Kahn's Yale University Art Gallery.

The project extends the University’s arts district westward, forging new urban relationships with the city at the edge of the campus and reclaiming what was formerly a derelict parking lot. The project reestablishes street frontage and raises parking off the ground. The new gallery facing Edgewood Avenue is coincident with existing historic structures. At night, the Sculpture Building illuminates the block, creating a safe passage from the main campus to the residential area at the campus edge. A University security office located in the parking structure benefits both students and the community.

Connectivity is further restored by the creation of safe bus stops; five bus lines stop within 1/4-mile of the site. Of the project's parking spaces, 6% are reserved for carpools and vehicles that run on alternative fuels. A consolidated program for the School of Art eliminates the need for driving between campus buildings. The Sculpture Building also includes 12 bicycle stalls as well as showers and changing rooms to encourage bicycle commuting.

Metrics

Land Use & Site Ecology

The project is located near Beaver Ponds Park, which has lacustrine habitat, and Edgewood Park, which has riparian habitat. The site is also near East Rock Park, which contains significant open space, and the more urban but well forested New Haven Green. The green roof on the Gallery and the native landscaping, which includes mature trees, serve as a connective habitat patch for birds moving through the urban corridor between these parks.

To remediate this former brownfield site, the project team removed contaminated soil from the site prior to construction. The landscape was designed to reduce the site's ambient temperature and its contribution to the urban heat-island effect. The cooler site also slightly reduces the cooling loads of surrounding buildings and sets a precedent for future development.

New Haven processes stormwater through its sewage plant, resulting in sewage overflow into Long Island Sound during heavy storms. The project team implemented several strategies to avoid contributing to this problem. The team replaced previously impervious surfaces with a rain garden, porous asphalt, native plantings, and shade trees. The team also designed a green roof for the Gallery, which, once mature, will reduce annual runoff by approximately 85%. Combined, these strategies reduced the site's stormwater runoff by 36%.

Bioclimatic Design

Based on solar analysis, the project team oriented the Sculpture Building along an east-west axis, minimizing eastern exposure and almost eliminating western exposure. The team also developed the facades and shading to optimize daylighting while minimizing summertime heat gain and allowing wintertime heat gain. Finally, the team performed a study on how alterations to the geometry and glazing configurations of the studio spaces would affect daylight levels and distribution.

Light & Air

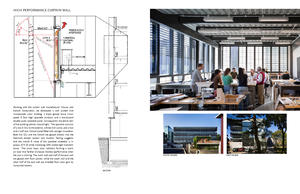

The curtainwall construction features a large expanse of windows in each studio space. This glazed area provides 2% daylight factor levels as well as access to views of the surrounding environment and provides operable windows to allow personal control over ventilation. To enhance occupant control over the interior environment, every space is provided with interior shades.

Daylight-dimming ballasts in all perimeter occupied spaces subtly respond to daylight levels, providing full electrical lighting when natural lighting falls below 30 footcandles. The first-floor shop spaces have been outfitted with clerestory windows and non-dimmable ballasts to eliminate all distractions, as safety is paramount in these areas.

A displacement ventilation system protects indoor air quality. Workshops are equipped with comprehensive exhaust systems that adjust to the number of machines running, ensuring the removal of airborne irritants while preventing a constant exhaust that would waste energy. The project team installed an air-monitoring system to ensure that hazardous materials are not introduced on the studio levels and recirculated through the building. This sampling system can be used for routine monitoring and diagnostics in the event of an air-quality problem.

Metrics

Water Cycle

A comprehensive site and building water-management approach yields significant water savings. Waterless urinals, dual-flush toilets, and low-flow faucets reduce water use, and rainwater collected from the roof of the Sculpture Building and surrounding landscape is used to flush toilets. The stormwater is initially stored in a 5,000-gallon outdoor tank, sized to allow for storage during droughts. From the outdoor tank, water is pumped into a 400-gallon indoor tank, where it is disinfected before being used to flush toilets. This strategy completely eliminates the use of potable water for sewage transfer.

The project team selected an ozone treatment system for the rainwater because it avoids the hazards associated with the production, handling, and disposal of chlorine. This choice reduced the consumption of chlorine by two to eight pounds per year. The ozone system was selected over copper/silver and ultraviolet systems due to concerns involving maintenance costs and effectiveness, respectively.

Energy Flows & Energy Future

The building massing takes advantage of self shading during the summer and reduces exterior surfaces that are exposed to intense solar heat gains to minimize cooling loads. The use of high performance glazing and insulated walls reduces heating and cooling demands and CO2 production. Operable windows allow the building to ventilate naturally in spring and fall, reducing fan loads and providing surplus ventilation capacity for high occupancies, while connecting the building to its external environment.

Abundant daylighting reduces energy used for artificial lighting, improves the indoor environment, increases productivity, and provides a connection to the outdoors, while reducing the amount of energy used for artificial lighting. High efficiency lighting fixtures rely on occupancy sensors in all spaces and dimmers set at 30 footcandles in all undergraduate classrooms, studios, graduate studios and fourth floor lobby.

A displacement ventilation system, in which air supplied at low velocities and higher than usual supply temperatures, reduces energy use and CO2 production by decreasing the amount of heating/cooling required. Premium-efficiency motors and high efficiency hot water condensing boilers which exceeds ASHRAE 90.1-1999 minimum requirements have been installed.

Concrete slabs have been left exposed internally to reduce the demand on heating and cooling systems, and to aid in the storage of recovered heat in winter.

Metrics

Materials & Construction

The Sculpture Building's aesthetic was derived entirely from the desire for superior environmental performance. As seen against Yale’s gothic structures beyond, the building has an elegant contemporary gothic fenestration that mitigates solar gain. The interior spaces feature utilitarian, unfinished surfaces with exposed steel structures, designed to inspire and support the creative activity demanded by the program. Columns and beams are all narrow eight-inch-wide flange sections, with beams lapping over girders in a simple yet eloquent woven pattern. Flexible light fixtures mounted to continuous tracks and the fire-suppression system piping completes the exposed three-dimensional plaid assemblage of building systems.

The sunscreens on the Gallery are made of reclaimed cedar. Measured by cost, 42% of all materials were manufactured within 500 miles of the project site; of these, 93% were manufactured using raw materials harvested within 500 miles of the site. Collection and storage facilities have been provided to facilitate post-occupancy recycling.

Long Life, Loose Fit

The studio building was conceived as a loft to remain as flexible as possible. The first floor houses an array of metal, wood, digital fabrication, and paint shops along with office and classroom space. The upper three floors are flexible and can be divided to suit the needs of the inhabitants. To support this, the project team designed the infrastructure so that nothing would need to be moved to allow modification of the interior. The internal organization of the studio building corresponds to the 2.5-foot module of the curtainwall mullions, and the lighting fixtures allow for flexibility of fixture types to support the needs of architecture students and remain effective for end users. Because the building was intended to serve as a swing space for the first year of occupancy, the design minimizes the amount of renovation required to accommodate its permanent residents.

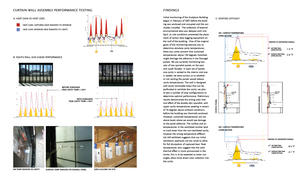

Collective Wisdom & Feedback Loops

There has been significant post-occupancy testing of the façade for thermal performance. Temperature, humidity, and solar radiation monitors were installed within the rooms and on the roof. Within the wall structure, the temperature of the cavity between the translucent insulation panel and the one-inch insulated glazing unit was analyzed. Two panels with ventilation gaps were also monitored for temperature and air movement. Findings indicate that temperatures in the chambers are nearly 140°F but will not damage the translucent insulation panel. The initial data from the vented test units show little air movement, indicating the need for further testing and perhaps enlarged vents, along with a system for venting the air to the outside and a system shutoff for use in the event of fire. The systems required for the next generation of this solar wall are under investigation.

In an effort to create habitat and a great ecology, the project team preserved trees on the site. An unexpected outcome of this is the significant hazard the glass curtainwall presents for birds. As a result, we have undertaken a study of technology from the fields of agriculture, aviation, and waste disposal to determine which technologies could minimize the hazard. The findings will be implemented at the structure, will inform future projects, and will be provided as a resource in publications such as BuildingEnvelopes.org.

Other Information

Cost data in U.S. dollars as of date of completion.

-Total project cost (land excluded): $35,000,000

The rainwater-harvesting systems are expected to save approximately $9,000 per year, and the low-flow plumbing fixtures are expected to reduce water expenditures by another $14,000 per year. The curtainwall and lighting systems are expected to reduce energy costs by $20,000 to $25,000 per year.

Predesign

The predesign and programming for this project were undertaken by another architect. When KieranTimberlake embarked on the design, the firm determined that the program did not meet the client's requirements, so it undertook a programming study during the design phase.

Design

This structure's exceptional environmental performance resulted from the fully integrated design process, which took the project all the way from programming through occupancy in only 22 months, less than half the time of a typical university project.

Although the client aspired to a LEED Silver rating, the project ultimately achieved a Platinum rating. The higher rating arose from the integrated process, not from exceptional expenditure for high-performance systems. The entire design team met with the client weekly for several months at the project's outset. All members present discussed the options as the team developed the program, site orientation, massing, landscape, structure, and curtainwall.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Owner/developer | Yale University | New Haven, CT | ||

| Contractor | Anthony | Miliote | Shawmut Design and Construction | Boston, MA |

| Environmental building consultant | Paul | Stoller | Atelier Ten | New Haven, CT |

| MEP, fire protection, and civil engineer | Ted | Dabrowski | BVH Integrated Services, Inc. | Bloomfield, CT |

| Structural engineer | Jon | Morrison, P.E. | CVM Structural Engineers | Wayne, PA |

| Lighting designer | Brian | Stacy | Arup Lighting | New York, NY |

| Commissioning agent | Brad | Jones | Sebesta Blomberg | Woburn, MA |

| Landscape architect | Jose | Alminana | Andropogon Associates, Ltd. | Philadelphia, PA |